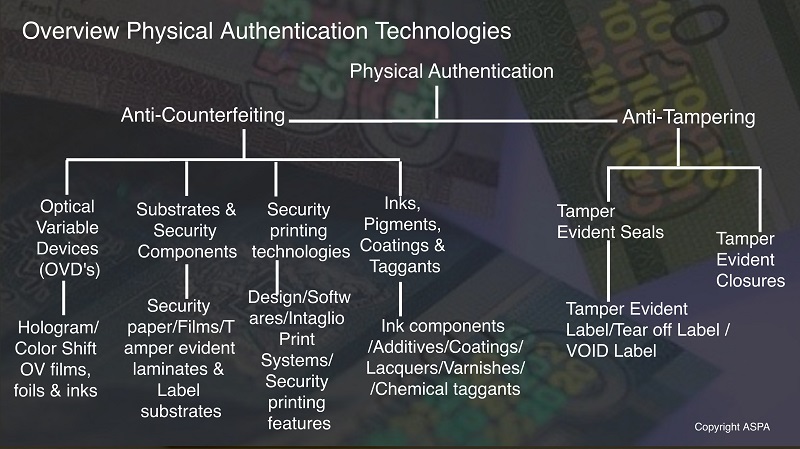

Physical Authentication

With the advancement of desktop publication & smart scanning technologies, it is becoming easy for counterfeiters to replicate product labeling. Even an expert cannot identify the difference between fake vs. genuine products. In this scenario, physical authentication technologies have played an essential role in combating counterfeiting.

There are end numbers of Authentication/traceability technologies, solutions, and systems available to manufacturers, ranging from the simple but effective, through to the highly sophisticated and extremely secure. The majority can be implemented on one or more of the packaging components, but some features can even be applied at the product level, either by direct marking or by using physical or chemical markers within the formulation.

To understand them according to your requirement, we suggest you to first consult the section Overview Authentication for through understanding of the document.

These can be used for anti-counterfeiting, anti-tampering and track and trace. According to product packaging, these can be classified into four basic groups.

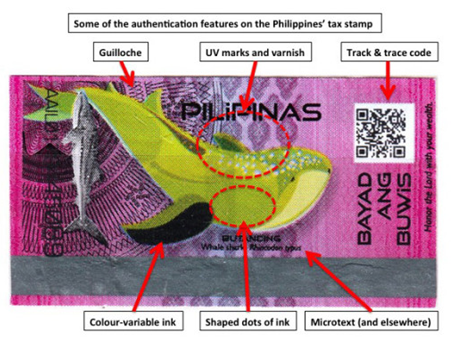

Security Designs: The design of secure and authentication labels/products is fundamental and must facilitate product for easy identification, its enhancement and integrating of anti-counterfeiting features. During the designing of the label, one can add many hidden and visible elements such as Guilloche’s pattern, Linework fractals, Registered images, Relief images, Special raster’s, Variable line thickness or line modulation, Micro text, screens etc. For example, in 2012, the Philippines, developed a stamp design reflecting its heritage using various overt, covert, and forensic security features. Due to the stamp’s functional design and non-intrusive nature, taxpayers readily adopted its use, resulting in a 95% market penetration (see figure 1).

Security Substrates: A security substrate constitutes the starting point of virtually all systems. In the liquor industry, the security label is used either are paper or polyester based. Paper is a standard substrate, and its application allows users for easy integration of other anti-counterfeiting features.

Optical Security Technologies: Optical authentication technologies such as optical variable device & inks (OVD’s / OVI) provide a dual role. These technologies assist brands, enforcement & consumer in instant and easy identification. While they help in easy identification, it is tough to copies these features as these provide triple layers security of multiple overt, covert, and forensic features. OVD’s technology such as high-end security hologram also ensures tamper resistance. That is the reason; these are used by Tax Stamp & Banknote authorities across the globe. In India, more than 75% of tax stamps used by the State Excise Department are based on Optical technology (security hologram).

Security Inks: Security inks are one of the perfect media of usage for brand protection and product authentication. Like almost all types of labels and packaging subjected to a printing process of some sort, these security inks added an effective solution to security problems. Close co-operation at an early stage between package and label designers, printers and a specialist security ink manufacturer can be a cost-effective way of protecting packaged and labeled goods. There are various options available in security inks, which include.

- Invisible ink

- Solvent Sensitive Ink (reactive)

- Thermochromic inks

- Optically variable inks

- Magnetic inks

- Luminescent inks and laser-activated etc.

Figure: Example of the Philippines’ tax stamp, source: https://www.reconnaissance.net/

Chemical, molecular, and nanotechnologies: In addition to design, optical & printing technologies, recent developments in nanotechnology have enabled significant improvement in the field of anti-counterfeiting measures. An emerging class of covert and forensic level technologies that utilize unique and highly engineered particles to construct specific signatures which can be detected sometimes in the field, but more often in a laboratory. For example, usage of fluorescent nano structures & DNA tags. The DNA molecules are added to the product’s raw material during the production process. Only one ppm (one part per million) is required to mark the material uniquely. That is one gram per ton of raw material. Therefore, their material properties remain unchanged.

With the advancement in technologies, all these can be used as overt, covert, and forensic. In ideal conditions, the solutions must be a combination of physical + digital technology. While physical must ensure tamper resistance, digital will provide real time data intelligence, transparency, and traceability. One should always focus on solutions rather than relying solely on specific individual technology.

For more information, understanding digital authentication solutions, click here

For more information, on selecting authentication solutions, click here

For more information regarding solutions according to particular industry, visit the industries section.